High tip buckets and other buckets with high tip

Do you need a high tip bucket for grain, pellets, wood chips or the like? High tip buckets provide extra lifting height for loaders, and JST has a wide selection for both large and small machines. The buckets are available from 315 liters up to 17,730 liters – with a good selection of sizes in between.

Are you working with heavy material like scrap metals or iron? Choose a JST loading bucket with high tip and do the job without problems. Click below to see the different types of buckets with high tip, and get access to details such as widths, volume, weight and prices in our catalogue.

Do you need something that isn’t standard? Please contact us – we can always find a solution.

High tip buckets in stock

We often have high tip buckets for loaders of 8.5 – 20.5 tons in stock for immediate delivery. Please contact our sales department to hear, what is in stock at the moment.

High Tip Buckets | 1.2 – 8.5 tons

Our high tip buckets for 1.2 – 8.5 tons are made for smaller loaders such as mini loader, mini articulated loader, front loader, backhoe loader, larger telehandler and machinery with Z-kinematics.

In this category there is also a side tip bucket for loaders and backhoe loaders 5.5 – 8.5 tons.

For some articulated machine types, a box must be built into the bucket for the link-arm.

Optional extras: Cutting edge, heel and safety hook (Pejo)

High Tip Buckets | 8.5 – 32 tons

We make high tip buckets for loaders from 8.5 tons to 32 tons. These buckets are made for loose materials such as grain, pellets or wood chips with a density of up to 1 ton per m3. With an HD (heavy duty) bucket, you can work with materials with a density up to 1.6 tons per m3.

A larger proportion of the bucket is made of high strength steel H450, which is 3-4 times as strong as ordinary structural steel.

All of these buckets are with double damped cylinders and rubber stops between bucket and rear frame.

If you wish to have peepholes in the top of the rear bucket part, this can be selected as add-on.

Other additional extras: Three-part bolt-on blade, cutting edge, riddle spill guard, spill guard, spill plate over rear frame and central lubrication system for six lubrication points.

You can choose different brackets, so that the bucket fits to your machine and you can add a Pejo safety hook.

We also offer a high-tip potato bucket for loaders from 11 – 18.5 tons.

High tip buckets in stock

We often have high tip buckets in this category in stock. Please check out availability with our sales department.

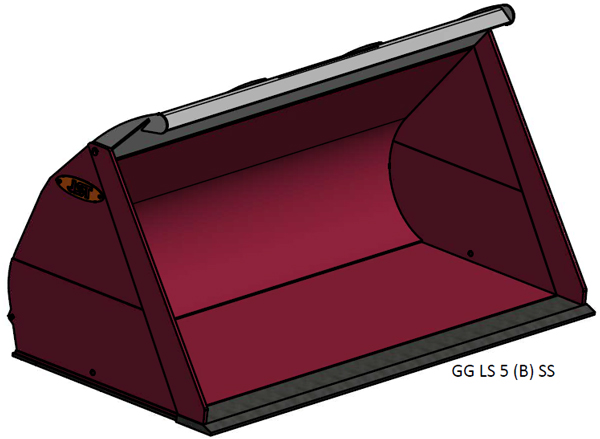

Loader buckets with high tip | 8.5 – 40 tons

Do you work with heavy materials? And do you wish to have that extra lifting height on your loader bucket that the high tip provides?

Then a JST loader bucket with built-in high tip would be a good solution for you. Our loader buckets with high tip are stronger than our high tip buckets, so if you are working with materials such as scrap metal and iron, then the solid loader bucket is the right choice for you.

The loader buckets are available with different side profiles and all sizes are available in HD (heavy duty) where the bucket is made of high strength steel H450 (3-4 times as strong as normal structual steel).

You can add high tip to our loader buckets for machines from 8,500 – 40,000 kg.

Other buckets with high tip

Our potato bucket and root crop bucket for front loaders and loaders with an operating weight of 3.5 – 8.5 tons are available with and without high tip. For high tip on some articulated machine types, a box must be built into the bucket for the link arm.

We also offer a high-tip potato bucket for loaders from 11 – 18.5 tons.

We also offer grapple buckets and low profile grapple buckets with high tip for 1.2 – 18 tons.

Kinematics on loading boom | loader 8.5 – 40 t

Kinematics on the loading boom are important when choosing your bucket, since our buckets are adapted to the kinematics of the loading boom.

Z-kinematics

Z-kinematics is the most widely used system for loading tasks and is known for being a versatile system. Z-kinematics has a good breaking ability, but is less accurate than parallel kinematics, especially in the high position.

Our high tip bucket model Z is compatible with Z-kinematics. In some cases, the loading bucket cannot be quite as open as it can on other kinematics models.

Parallel kinematics

Parallel kinematics is widely used where the machine is mostly used for handling tasks with e.g. pallet forks. For this type of tasks, it is important that the arm can maintain a horizontal/parallel position in relation to the ground when lifting. It is strong at the top of the lift and is therefore also good for high tip buckets.

The system offers the possibility of using tall, upright attachments such as our high tip bucket model P, upright volume buckets or clamps.

TP kinematics

TP kinematics (Torque Parallel) only excists on Volvo machines up to and including L220. TP kinematics combines the advantages of Z-kinematics and Parallel-kinematics.

For TP kinematics you can use tall, upright attachments such as our high tip bucket model P or upright volume buckets or clamps.